Completion Wireline Services

ABOUT RANGER COMPLETION WIRELINE SERVICES

We rise to the challenge

Ranger’s Completion Wireline Services rises to today’s challenges of increasing operational efficiencies associated with pumpdown, plug and perf operations. Ranger offers the scale and footprint with experienced crews, state-of-the-art technology, and standard operating procedures to deliver reliable wireline operations and high run efficiency.

WIRELINE PERFORATING SERVICES

Ranger uses modern, fit-for-purpose wireline trucks and state-of-the-art systems to maximize safety, increase reliability and improve efficiency.

CommandPerf® Stage Perforating

- Best-in-class technologies.

- Plug-and-play safe fire perforating systems.

- Internally oriented gun strings.

- Verified operating procedures.

- Established, proven crew & equipment teams.

- Factory assembled gun components for maximum reliability.

CommandReach Risk Mitigation

- Wireline & Pump Down Modeling.

- Real-time Monitoring.

- Combined Pump Down Services with dedicated 2250-2500 HP units.

- Running parameters designed to prevent plug presets.

- High pressure and extended reach wells.

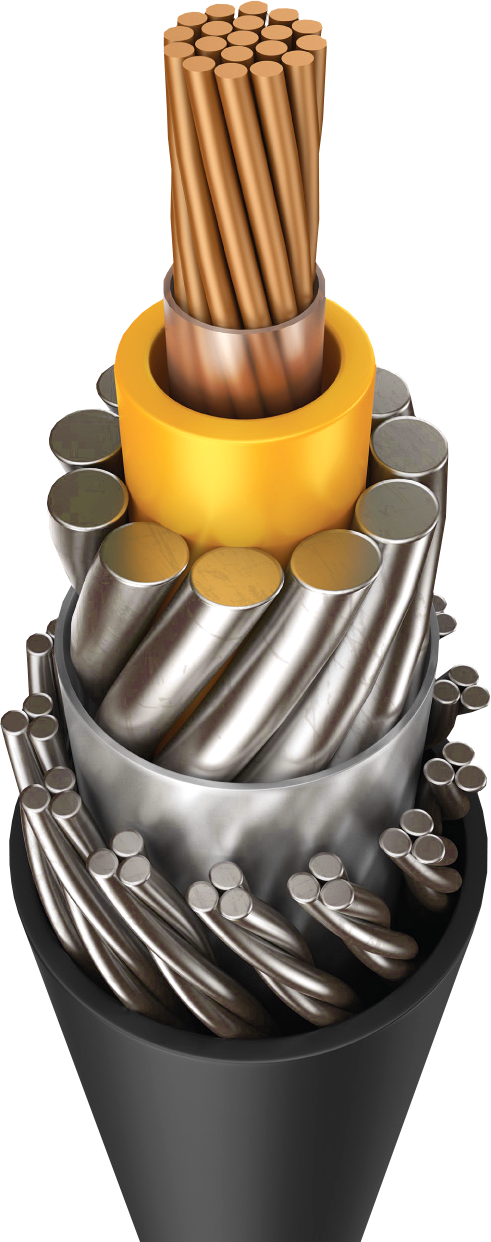

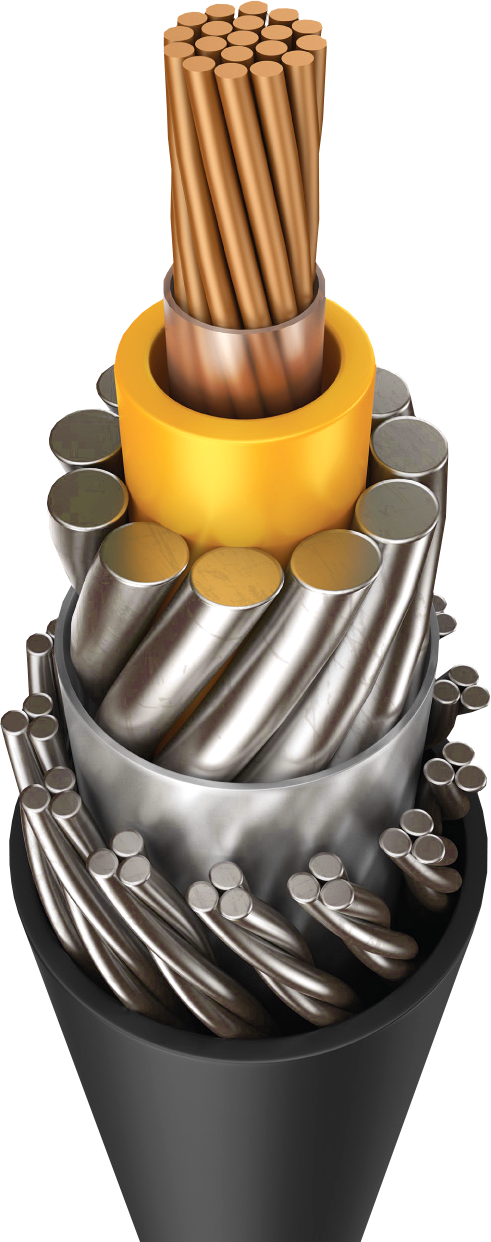

GREASELESS CABLE

Ranger uses wireline covered with a polymer jacket for a cleaner, faster and safer operation. Conventional wireline requires pressure control operations using grease that can be messy on location.

- Cleaner, safer, and environmentally friendly operations

- Faster running speeds due to reduced friction coefficient in long laterals

- Faster rig up time since grease injection system is not required

- Extended reach with 40kft cables in long laterals

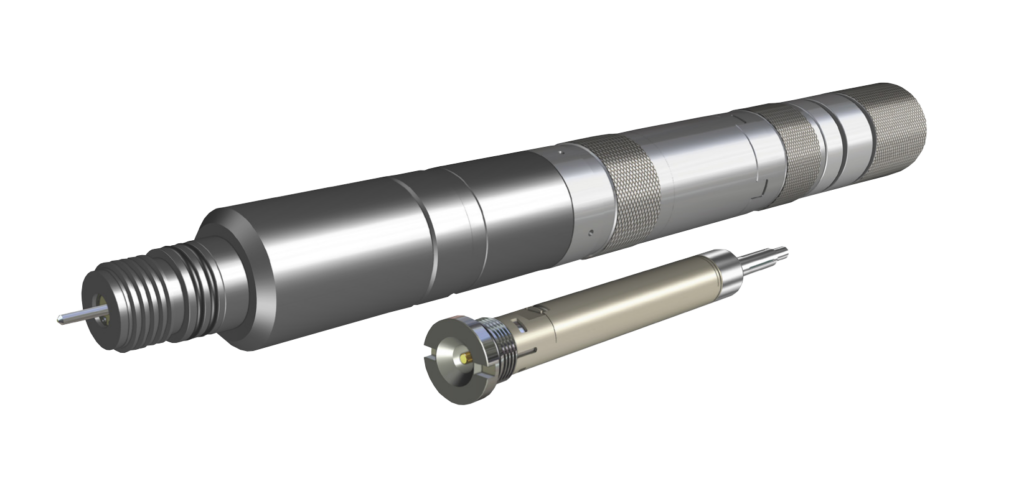

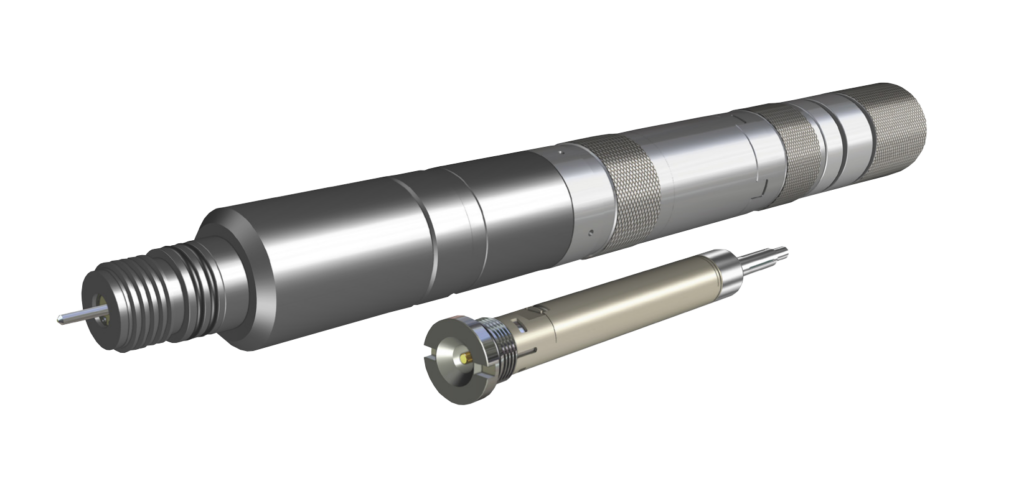

WELL SWAP SYSTEMS

Ranger uses innovative technology to allow remote operation of wellhead connections. The advanced systems replace legacy threaded connections between the pressure control equipment and the wellhead with a remotely operated connection for a much safer, more efficient operation.

- Removes personnel from high pressure areas when making or breaking connections

- Incorporates multiple safety redundancies to signal latch status

- Enables frac and wireline simultaneous operations

- Increases well swap efficiencies

DOWNHOLE CABLE HEAD RELEASE & TENSION TOOLS

Ranger provides additional risk mitigation services with downhole release tools and tension tools to help ensure safe operations

- Addressable ballistic release tools and mechanical release tools can be run independently or in combination to protect the wireline and avoid complex fishing operations

- Downhole tension tools improve pump down efficiency and speed while reducing risk and uncertainty in longer laterals.

- Wireline and pump down modeling helps in pre-job prep and operational efficiency.

PUMP DOWN SERVICES

Ranger uses 2250 – 2500 HP quintuplex pumps including tier 4 emissions standards. Combining Ranger’s wireline perforating and pump down services maximizes safety and operational efficiency through integrated safety, quality and communications systems.

- Integrated wireline perforating and pump down services

- Operator controls pump from wireline unit for optimum communications

- Common standard operating procedures and safety standards

- Maximize safety and operational efficiency

- More stringent emissions standards

- Crew synergy with pump operators familiar with wireline operations